What are some of the things you consider when looking for wear parts for your shredder? Out of the many considerations, the source of the shredder parts you have chosen determines the kind of service that you will get. Aftermarket shredder wear parts make one of the best options today. This is based on the assorted advantages that one acquires upon choosing such. If you are considering buying shredder wear parts in the aftermarket sector, then here are the benefits you stand to enjoy:

Fair Budget

Are you the kind of person who develops Goosebumps when budgetary concerns are raised, particularly with reference to shredder wear parts? Well, it is quite understandable that a person with a stringent budget will always seek cheap deals, which are not always available. The main way through which you can access cheap deals for shredder wear parts is through the aftermarket sector.

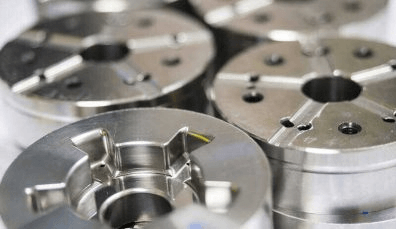

Custom Shredder Wear Parts

Individuals who are familiar with shredder usage and operations may consider it necessary to customize different parts as a way of ensuring efficient operations. Custom shredder parts are usually not available at the original manufacturer. However, custom parts can be accessed in the aftermarket sector. All you need is to provide specifications for your order and get exactly what you want.

Availability

Any person who has had a bad experience in sourcing shredder wear parts can confirm that it is not worth it to look for original parts when the original manufacturer is not within the vicinity. That is why aftermarket shredder parts manufacturers are available. Their role is to ensure that the shredder wear parts you seek are available with maximum convenience. Therefore, settling for wear parts from the aftermarket sector is an advantage in terms of availability.

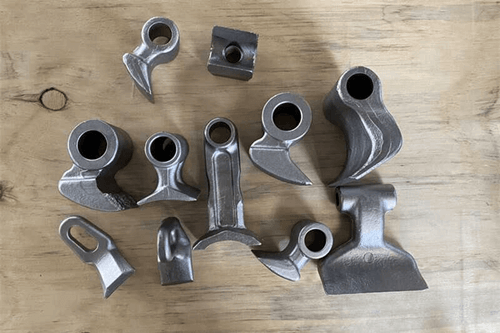

Best Quality

Most people think that the only way one can access quality shredder wear parts is by going to the original manufacturer. While this is essentially true, you can still get the best quality in the aftermarket sector. In fact, the aftermarket sector provides the best quality at cheap deals, hence you should consider the option.

If you are looking for a good aftermarket manufacturer, click for info about one of the reputable aftermarket manufacturers in the market today. They are best known for quality and affordable products.