If you want to buy forging steel products, there are a few things you need to consider. First, you need a reliable supplier whom you can trust to meet your expectations. It is important to do thorough research so that you can get a good supplier. You need to follow several guides carefully to get the best supplier for forging steel products. Below, we have put together some of these guides.

Industrial experience

There are some new suppliers in the industry, and without researching, you might find yourself buying from them whereby offering you the quality you expect can be a big issue. This is why it is important to check the experience supplier has in the industry. This can be determined by their length of time in the industry.

Customer’s reviews

Another thing you need to look for is customer reviews. In this case, visit various suppliers’ platforms and see what people are saying. If people are complaining about the supplier, you should reconsider dealing with them. This is an important way to know a reliable supplier.

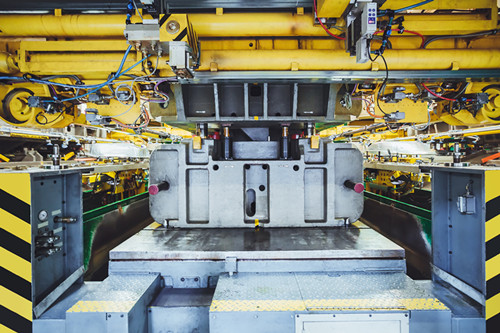

Quality factory

The state of the factory the supplier is using in the production of forging is another factor to consider. The quality of the factory plays a major role in the quality offered. Therefore, check whether the factory is equipped with the latest technology. Still, under a quality factory, check on the technicians whether they are well skilled to provide good quality.

Cost of forging

The cost of forging is another factor you should consider in suppliers for forging steel products. Ensure the forgings offered are affordable and the quality is the best. Be on the lookout for suppliers offering cheaper products due to compromised quality.

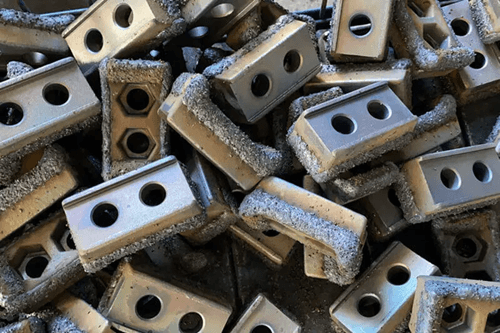

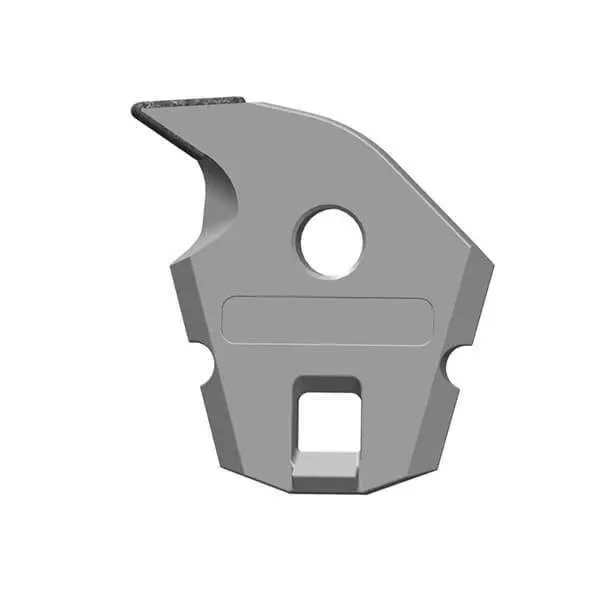

Production versatility

Another important factor you should consider is the versatility in production. Can the supplier produce a range of products? You need a supplier that can offer you with variety of products you might need. This is important because you do not need to move from one supply to another. It should be all under one roof.